Chiplets are a type of chip packaging technology developed by Advanced Micro Devices (AMD) in collaboration with Intel and Taiwan Semiconductor Manufacturing Corporation (TSMC) that enable partitioning of what traditionally was a single, monolithic piece of silicon into multiple smaller “chiplets” that are then combined on a single package. This new technology allows the reuse and reconfiguration of existing chiplets to build custom system-level solutions from platform components.

Chiplets provide an efficient solution for improving performance, scalability, cost and security within computing components such as CPUs, GPUs and others. By using chiplets for these tasks instead of monolithic chip designs, it is possible to upgrade each component more quickly and easily without sacrificing performance or clock speed power efficiency. In addition, due to their modular nature, the individual chiplets don’t need to be resized for different applications as can happen with traditional motherboard design approaches.

The concept was further advanced when Microsoft announced Project Chalkboard at its 2017 Windows Hardware Developer Conference (WinHEC). In this initiative, Microsoft worked closely with AMD and other industry partners to create systems on an industry standard called Common Co-Design Architecture (CCA 2.0). CCA 2.0 uses chiplets as the basis for developing sophisticated high performance computing systems while allowing all vendors in the industry to pool together their intellectual property on a common infrastructure. The advantage of this model is that it allows vendors such as Microsoft and Intel to leverage their IP expertise in diverse application areas while still providing customers with access to unified platforms that are optimized across all segments quickly and reliably.

History of Chiplets

Chiplet technology began to gain traction in the early 2020s when major players like AMD Intel, TSMC, Microsoft and others established the universal Chiplet standard. Chiplet technology has since revolutionized the way semiconductor design, fabrication and assembly is carried out and created a new era for the industry.

This article will explore the history of Chiplets and its significance to the semiconductor industry.

AMD beats Intel with first CPUs that have Xbox-like security for Windows

AMD, Intel, TSMC, Microsoft and a few other leading industry players have been working to establish a universal chiplet standard over the last several years. AMD was the first to initiate the development and implementation of this open-source standard with their introduction of chiplets in late 2019. The company coined the term “chiplet” to refer to any component made in a standardized form factor that can readily link together with other components. AMD’s chiplets offer manufacturers the ability to reduce their total bill of materials by using fewer specialized components. At the same time chiplets simplify design complexity for SoCs, improve performance and reduce power consumption for higher efficiency.

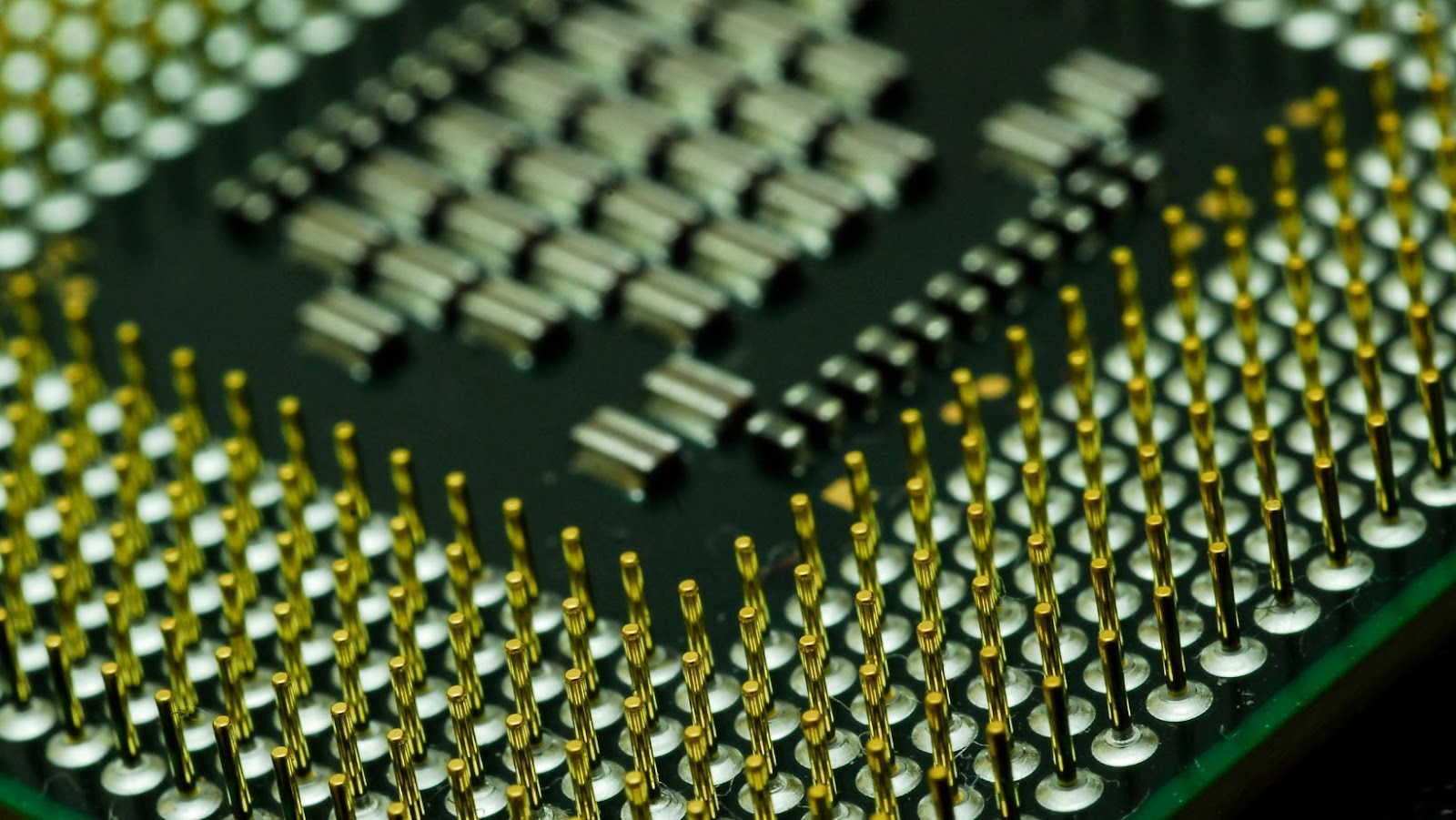

The company debuted its first set of chiplets as part of its Ryzen 3000 series processors utilizing an 8-core hyperthreaded CPU, four memory channels and 16 lanes PCIe 4.0 communication interface built into each chiplet. Despite only introducing its first generation of Zen 2-based products at that time, chips are already being produced at both 5 nm and 7 nm processes sizes on TSMC’s Foundry lines with no additional customization required beyond what has already established by the companies involved in this new manufacturing protocol.

Intel’s Introduction of Chiplets

Intel coined the term “chiplets” in 2017 with the intention of bringing modularity to modern processors. By combining high-speed networks on chip (NoC) circuitry, chiplets could split a processor (or multi-processor) into advanced computing cores and accelerators that can be developed and manufactured independently. With this approach, companies like Intel and AMD could leverage economies of scale when developing core architectures by designing and manufacturing multiple types of advanced chiplets on a single substrate, thus accelerating time to market without sacrificing maximum performance.

In 2019, hardware companies such as Microsoft, Intel and TSMC partnered up under the “Chiplets Ecosystem” Program to develop a new standard for chipplet architectures. By providing silicon designers with unified standards for designing multi-chipplet systems within their own ecosystems, they sought control over their respective characterizations designs while making it easier for independent developers to collaborate and accelerate development of next generation system-on-chips (SoC).

Ultimately this initiative laid the foundation several current product designs that range from datacenter GPUs to advanced FPGAs powered by AI algorithms that may eventually lead to natural language processing devices personalized for individual users. This open-standard brings an unprecedented level innovative possibility across a number of industries especially given AMD’s current plans for competing 7nm microprocessors with greater interconnectivity than ever before.

Benefits of Chiplets

Chiplets are an increasingly popular concept in the chip and microprocessor industry. The idea is that small “chips” called Chiplets can be connected together to form a larger, complex and more powerful microprocessor. Companies such as AMD, Intel, TSMC, Microsoft and others have all come together to establish a universal chiplet standard (chiplets) that can be used in a variety of applications.

This article will discuss the benefits of using chiplets and how they can benefit the chip and microprocessor industry.

Cost Reduction

The Chiplets initiative offers significant potential for cost reduction due to components being sold independently from the entire product. The use of chiplets decreases the amount of design revisions needed in the development process and enables chipmakers to reduce their production costs by using existing, cost-effective designs and repurposing them for individual tasks. By using Chiplets technology, system designers will be able to select from a variety of pre-defined chiplet components which meet specific requirements without having to tailor designs or establish any proprietary relationships with vendors.

In addition, manufacturers have the capability to reduce their labor costs considerably through automation. Automation can be used to replicate processes and create mass production with minimal human interaction, leading to further efficiency and cost savings across the supply chain. As a result of this and other factors such as improved design scalability, faster time-to-market, increased flexibility in production runs, increased customization options, as well as enhanced scalability and better power management capability all contribute to reduced unit costs that have made Chiplets popular amongst major tech players such as AMD, Intel, TSMC and Microsoft.

Increased Efficiency

Chiplets—a class of components consisting of multiple, relatively small dies housed together in a single package—are growing in usage as technology advances. They are used in computer processors, FPGAs and many other applications, enabling the combination of multiple functionally independent chipsinto one large system-on-chip (SoC). Chiplet technology allows for a greater level of integration than is possible with individual components, and also provides numerous advantages such as increased performance, improved reliability and cost savings.

Chiplets enable powerful multi-die designs that can be implemented more efficiently than traditional monolithic chips or discrete components. By utilizing relatively small but powerful chiplets that serve different functions within an SoC, manufacturers can achieve better performance with lower power budgets and shorter development times. This helps to reduce the overall cost of the chip while increasing overall system efficiency due to simpler miniaturization processes. Additionally, because chiplets have smaller form factors than monolithic chips, they are easier to manufacture and test for compatibility with other parts within the same SoC architecture.

Moreover, multi-die designs enabled by chiplets help improve reliability compared to monolithic chips because if any individual chiplet fails or experiences a problem during operation it does not affect the entire SoC. This makes them well suited for mission-critical industrial and military applications where tight operating tolerances need to be maintained despite harsh environmental conditions or limitations on component sizes. The modular nature of these configurations also allows manufacturers to use different types of cores from various vendors within a single integrated solution — making them ideal for complex workloads or hybrid applications that require high levels of customization. Chiplete designs are increasingly being adopted by major semiconductor companies such as AMD, Intel, TSMC and Microsoft as part of their universal chiplet standardization efforts which will make component scaling easier across future generations of products.

Universal Chiplets Standard

In recent years, advances in chiplet technology have been developed by semiconductor giants such as AMD, Intel, TSMC, Microsoft, ARM, Qualcomm and others.

This universal chiplet standard is designed to enable easier and faster development of reliable, high-performance computing solutions.

This article will explore the concept of chiplets and the potential advantages of this new technology.

Established by AMD, Intel, TSMC, Microsoft and Others

AMD, Intel, TSMC, Microsoft and a range of other companies have come together to establish a universal chiplet standard for advanced semiconductor packaging. Called CEM 2.0 (Chiplet Electrical Model 2.0), the initiative provides an open industry standard specification for things like rigid chip-to-chip interconnects and high-speed signaling technologies that enable chiplets to easily integrate with each other.

CEM 2.0 will deliver unprecedented levels of modularity and flexibility to system developers by providing an open standard for power delivery, high-speed protocols, testing and diagnostics for chiplet integration into end products. This is expected to accelerate innovation in areas ranging from embedded AI/ML solutions to data center infrastructure.

The standard draws on many years of collective development experience from AMD, Intel Corporation, interconnect supplier Amphenol Corporation, OSATs (Outsourced Semiconductor Assembly & Test providers) AT&S and AOS Technologies as well as Microsoft’s cloud hardware platform team who developed the original CEM 1.0 version in 2018. TSMC has also contributed its expertise from over 20 years of developing packages for advanced semiconductors like GPUs (graphics processing units).

Achieving such an industry-wide effort required extensive collaboration between all members involved in the initiative which sought consensus across all design groups before its public release in July 2020 at Semicon West 2020 by the Semiconductor Industry Association’s3D InCites program sponsored by 3D InCites’ Chiplet Initiative.

Benefits of the Standard

The Universal Chiplets Standard (UCS) is a new initiative from the computing industry to pave the way for scalability and performance, as well as increased flexibility in system designs. The UCS will allow companies like AMD, Intel, TSMC, Microsoft and other electronics giants to create interchangeable components for chips. This means developers can quickly configure custom chips that are inexpensive, efficient and powerful enough for complex devices.

The UCS standard has several distinct advantages over traditional chip design methods. By creating components that are readily interchangeable between different vendors, businesses can reduce costs while improving product performance and increasing modularity. Additionally, end-users benefit from faster hardware development cycles as chip designers create customized chips with shorter time frames than in traditional methodologies.

As a result of this initiative, chip manufacturers can more easily tap into existing libraries of design elements in order to create new products quickly and efficiently. Companies no longer need to develop their own designs from scratch when they want to access existing intellectual property (IP). Furthermore, because IP blocks can be easily ported into any UCS-supported foundry or fab and using any compatible technology node or process line – not just on silicon – the cost savings achieved through UCS will be considerable compared to what would otherwise be required for full custom SoC developments.

This standardized approach also enables greater scalability across multiple fabrication processes with shortened design cycles; allowing businesses to tailor their products much more closely than before – with improved cost efficiency due less restrictive legal agreements between companies developing competing IP cores. Therefore, UCS promises small-scale cloud datacenters as well as advanced edge devices that boast higher performative benefits than ever before.

tags = Engineer, Arm, Google Cloud, Intel, Meta, Microsoft, Qualcomm, Samsung, cpus tsmc microsoft ryzentakahashiventurebeat